| It wasn't so long ago that treadplate was for walking on. Today, it's considered 'industrial chic' and is found everywhere from toolboxes to book covers and even trendy restaurant decor. The 'chic' stuff is aluminum - sometimes stainless - while the walking surface is still low carbon steel that gets galvanized, painted, or chrome-plated. It must be very clean before any final finish is applied, so fabricators become aggravated when they pull treadplate sheets from inventory and find them rusted. |

|||||||||||||

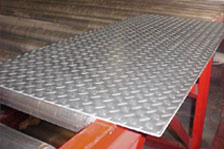

Figure 1: This 4-way treadplate was wet down to cause significant rusting as a test of SCS rust removal.  Figure 2: Closeup of the 4-way plate after the first SCS pass. Some rust remains 'sheltered' behind the raised lugs.  Figure 3: After its second pass through the SCS Sheet Line, the highly rusted treadplate was completely rust-free. |

More Prone to Rust AND Tougher to Clean Up Treadplate is inherently more prone to rust because it has small shelves and pockets where moisture can settle, even when sheets are stored standing on edge. If rust does develop, these same surface features make it much tougher to remove the rust. We wanted to see if the SCS process can 'cure' rust on treadplate. That would help users avoid scrapping rusted sheets or the effort involved in removing rust. We already proved SCS completely removes surface rust from sheets of hot rolled black, leaving a smooth, paintable surface. Also, the new style SCS 'brush' treats material with edge wave and surface irregularities better. But treadplate presents pretty extreme surface irregularities. |

||||||||||||

|

Running the treadplate through once, even at slower speed, beats running it through twice at full speed, especially when you consider the added handling required by the twice-through approach. We also found that complete rust removal (both sides of the lug) is a function of feed speed and brush wear, so we are developing guidelines for optimizing the once-through method. The Complete SCS Package for Treadplate The new SCS brush design allows us to process treadplate and give it the same clean, rust-resistant surface we get when processing conventional flat-rolled sheets. We now know that we can give the difficult treadplate surface the required bristle coverage and even achieve total surface rust removal using the reverse rotation method. What's more, if we Stretcher-Level treadplate to get it perfectly flat (after all, it is used for a flooring surface) you can avoid the punishment that treadplate inflicts on conventional roller levelers. |

|||||||||||||